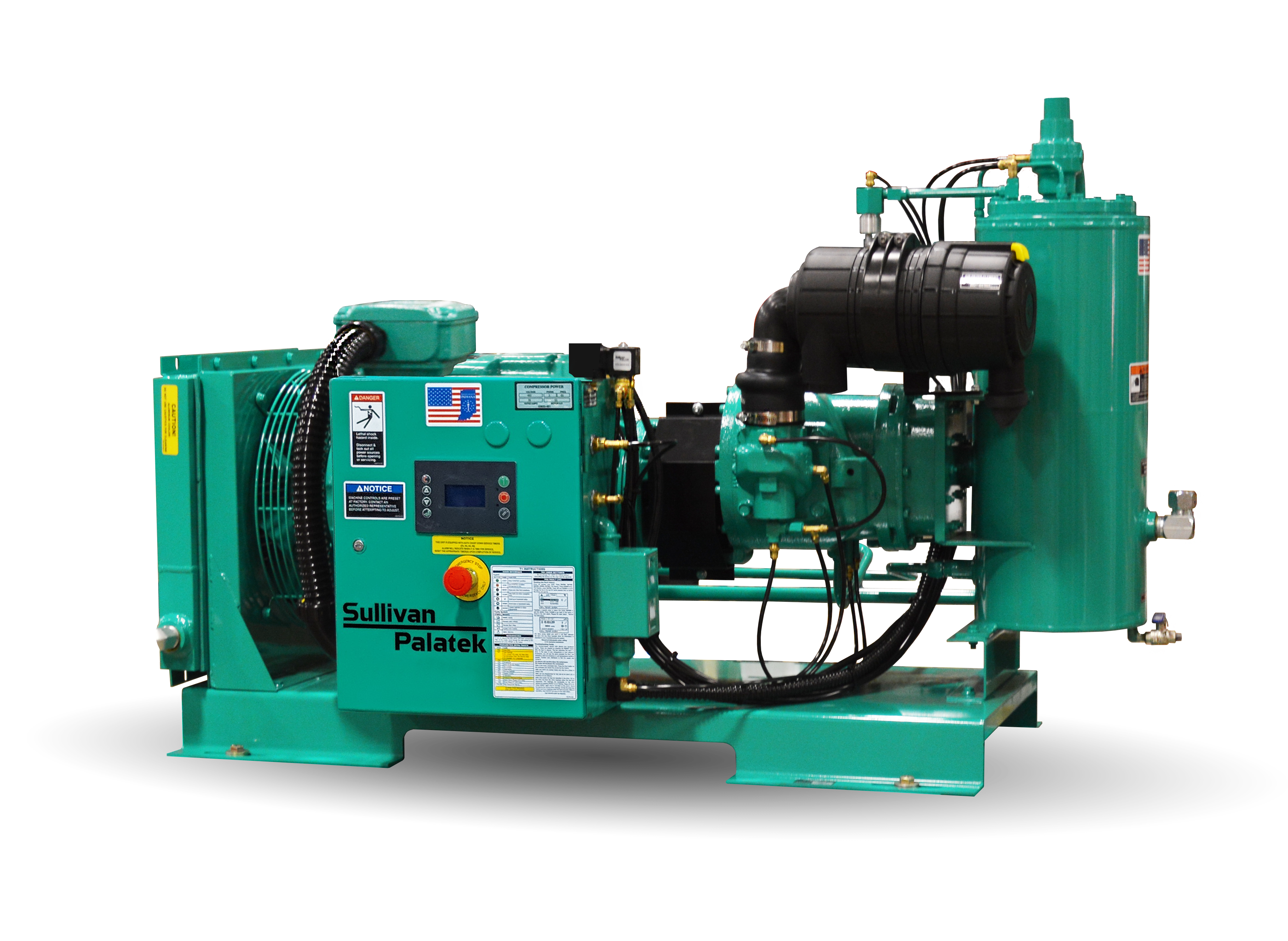

Sullivan-Palatek has developed the D-Series industrial electric direct drive rotary screw air compressor, which is designed to be dependable and versatile. These energy-efficient compressors come in a range of 15-40 hp and are equipped with an easily readable microprocessor. The coupling and air end are mounted to the motor C-face for convenience.

The D-Series compressors also feature a sizeable oversized separator element and sump tank, as well as easily replaceable oil and air intake filters. With their compact size and high reliability, these machines are perfect for smaller industrial settings like automotive shops, small machining facilities, and fabrication facilities. Additionally, the D-Series compressors have many easily accessible parts, resulting in a lower overall cost of ownership compared to our competitors.

Features & Benefits

- Microprocessor controller with sequencer, lead-lag, and remote monitoring for up to 8 machines

- Motor with Totally Enclosed Fan-Cooled (TEFC) enclosure type for indoor and outdoor use

- The motor starter has a water-tight, dust-tight, sleet resistant NEMA 4 enclosure for indoor and outdoor use

- The air end, manufactured by Sullivan-Palatek, has advanced rotor design features; oversize radial thrust bearings, and precision working rotary screws that provide virtually no wear

- Protective devices include class 20 solid-state overload relay, high temperature and overpressure shutdown switches, and anti-restart pressure switch preventing starting while air compressor is pressurized

- Coupling and drive: the compressor is flange mounted to motor C-face for positive alignment and directly coupled for increased efficiency

- Cooling system equipped with double pass air-cooled aftercooler with thermostatic control for maintaining the appropriate oil operating temperature within 15 degrees of ambient

- Using oversized coolers allows for greater cooling performance at high temperatures

- Oversized dry type air intake filter with easily replaceable elements

- One-piece lube fill elbow and level sight glass, a vented cap for pressure release when removing

- Inlet/check valve features a one-piece housing for dependable performance and complete modulation

| Model | Horsepower (hp) | Capacity (cfm) | Pressure (psi) | Motor Speed (rpm) |

|---|---|---|---|---|

| D-15 | 15 | *50.1 | 125 | 1750 |

| D-H15 | 15 | 46.5 | 150 | 1750 |

| D-20 | 20 | *80.2 | 125 | 1750 |

| D-H20 | 20 | 79.1 | 150 | 1750 |

| D-HH20 | 20 | 53 | 175 | 1750 |

| D-25 | 25 | *105 | 125 | 3550 |

| D-H25 | 25 | 92 | 150 | 3550 |

| D-HH25 | 25 | 80 | 175 | 3550 |

| D4-25 | 25 | *84.8 | 125 | 1750 |

| D4-H25 | 25 | *81.9 | 150 | 1750 |

| D4-HH25 | 25 | 74 | 175 | 1750 |

| D7-30 | 30 | 105 | 125 | 3550 |

| D7-H30 | 30 | 103 | 150 | 3550 |

| D-40 | 40 | 166 | 125 | 3550 |

| D-H40 | 40 | 103 | 150 | 3550 |

| D-HH40 | 40 | 100 | 175 | 3550 |

- Manufacturing

- Small Industrial Settings

- Automotive Shops

- Small Machining Factories

- Fabrication Workshops

- Food and Beverage

- Hospitals

- Water cooled

- Tank mounted:

- ASME coded 80, 120, and 200 gallon with auto drain

- Platform mounted:

- 19″ high to keep your unit off the ground and for easy maintenance

- Acoustical enclosure:

- Acoustical enclosure: Easy removable panels for faster maintenance and accessibility while keeping it quiet

- Lubricant:

- Lubricant: factory fill with Pallube 32, Pal-Extra 44, AFX 32, or Food Grade lubricant

- Wye-Delta and Solid States starters

- Air filter pop up indicator

- Deluxe gauge panel:

- Line pressure gauge, discharge pressure gauge, hourmeter, temperature gauge, lube filter and separator element diffenential gauges

- HATD shutdown switch:

- Shuts the compressor if high discharge air temperatuer are sensed

- Cold weather/low ambient package

- Separator trap:

- Captures and automatically drains condensed water, oil, and dirt

- VFD

- Variable Frequency Drive option, for more information, click here

*Capacity in accordance with CAGI / ISO 1217 (Annex C / Annex E)