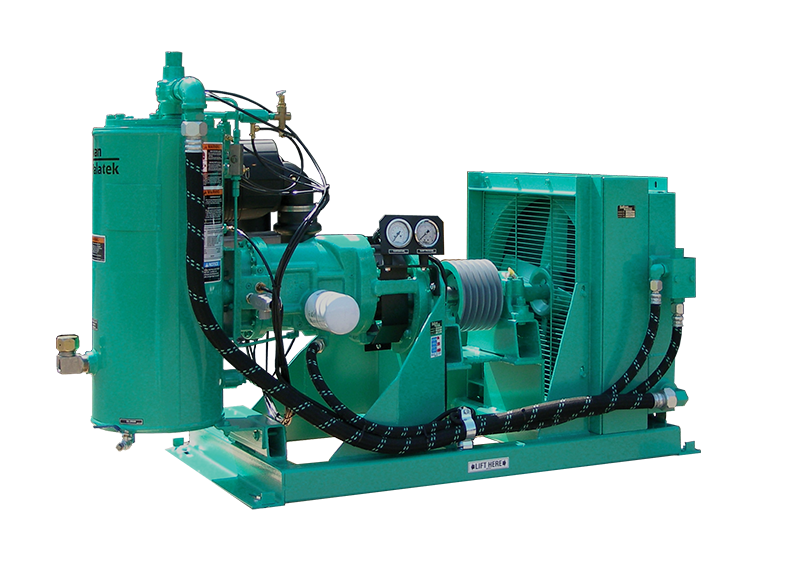

The Line Shaft Compressor series, also known as the LSC air compressor series, engineers the compressors to operate through a line shaft powered by a diesel engine. The compressors have pillow blocks that allow for convenient belt installation. They cater to a wide range of applications ranging from 15 to 60 HP with three different models available.

Furthermore, they have uncomplicated pneumatic controls and a temperature safety shut down feature to ensure their protection.

Features & Benefits

- COMPRESSOR – Continuous duty oil flooded rotary screw industrial air compressor

- PILLOW BLOCK – Solidly mounted and aligned to compressor shaft allowing drive shaft direct connection and minimizing power loss

- FRAME – Rugged steel construction

- COUPLING & DRIVE – Compressor is flange mounted to frame for positive alignment and directly driven by low maintenance coupling

- AIR INTAKE FILTER – Heavy duty dry type with replaceable element

- SEPARATOR TANK – ASME coded 200 PSIG sump tank, minimum pressure check valve, relief valve, high-efficiency replaceable oil separator element, fluid level sight indicator, and vented fill cap

- COOLING SYSTEM – Air cooled with air-cooled oil cooler and aftercooler. Compressor temperature maintained by auto-adjusting thermo valve

- CONTROLS – Full modulation pneumatic control for smooth control. Pilot unloader valve for minimizing power with no air demand.

- INSTRUMENTATION – Air pressure and discharge temperature gauges

- PROTECTIVE DEVICES – High temperature shut down switch for interfacing to driver’s safety circuit. Overpressure relief valve

- LUBRICATION – Factory filled with Palasyn 45. Equipped with microfiber full flow, spin on oil filter.

| Model | 15-30LSC | 40-50LSC | 50-60LSC |

|---|---|---|---|

| Capacity (cfm) | 55-115 | 165-210 | 215-265 |

| Maximum full load/unload (psig) | 125 | 125 | 125 |

| Minimum full load (psig) | 60 | 60 | 60 |

| Minimum required driver (hp) | 20-35 | 47-60 | 65-70 |

| Compressor RPM | 1750-3550 | 3550-4500 | 4250-5250 |

| Rotor diameter (mm) | 108 | 108 | 108 |

| L/D | 1.65 | 1.65 | 2.1 |

Communities that do not have electricity available or generators to power their compressor

- Wood shops

- Machine shops

- Painting facilities

- Platform mounted

- Tank mounted